FFKM Washers

FFKM Washers

Prevent leaks while distributing weight evenly under nuts and screws. These washers compress as you tighten to keep air and fluid in, and dust and contaminants out. Use them anywhere you need a tight seal, such as protecting electronics from moisture or keeping lubricants contained in machinery.

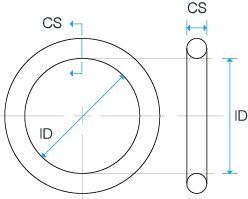

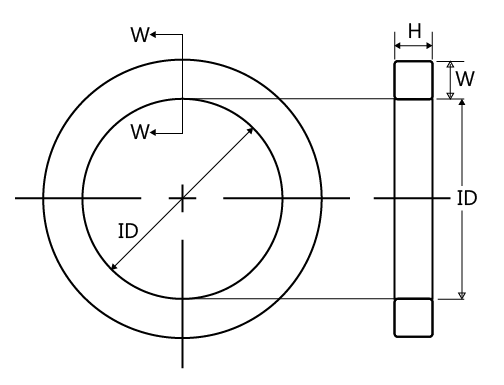

FFKM washer is a rubber ring with a rectangular cross-section. FFKM Washers are often used to replace FFKM O-Rings.Compared with O-Rings, washers are more capable of withstanding relatively higher pressure environments and they have a better service life. FFKM Washers are often used to replace FFKM O-Rings.

Product Features and Advantages:

In addition to been mostly used in static seals, FFKM rubber washers can also be used in piston seals and rod seals. Compared with O-Rings, the position of the mold parting line of rubber washers can be adjusted according to the sealing surface, and the requirement of no burrs can be achieved along with stricter dimensional tolerances. Compared with O-Rings, rubber washers can more effectively increase the filling rate of the seal in the groove, and reduce the possibility of leakage caused by the seal sliding or turning in the groove.

FFKM Material Characteristics

1. High temperature resistance: FFKM’s temperature resistance range can reach 320°C or even higher, which makes it perform well in high-temperature hydraulic and vacuum systems.

2. Chemical stability: FFKM material has a wide range of chemical inertness and can resist corrosion from most chemicals, including strong acids, strong alkalis, solvents, oils, etc.

3. Low gas permeability: Due to the high density of fluorine atoms in FFKM material, its gas permeability is extremely low, suitable for applications requiring airtightness, such as semiconductor manufacturing and vacuum systems.

4. Mechanical strength and elasticity: FFKM material has excellent mechanical strength and elasticity and can withstand high pressure and dynamic loads. Its high tensile strength and modulus make it perform well in dynamic sealing applications.

5. Compression set resistance: FFKM material has extremely low compression set, and its sealing performance will not be significantly reduced due to compression, thereby extending its service life.

6. Wear and tear resistance: FFKM material has excellent wear and tear resistance and can remain stable in harsh environments.

Application Areas

Chemical Industry: FFKM seals are able to withstand a wide range of corrosive chemicals and are widely used in pipe, valve and reactor seals to ensure safe and effective sealing.

Semiconductor Manufacturing: In the semiconductor production process, FFKM seals are used in vacuum systems and gas sealing applications to ensure no leaks and maintain a clean environment.

Pharmaceutical Industry: Due to its FDA compliance, FFKM seals are widely used in pharmaceutical equipment to ensure safety and reliability when in contact with pharmaceuticals.

Oil and Gas: FFKM seals perform well under high temperature and pressure conditions and are suitable for critical applications such as oilfield equipment, downhole tools and control valves.

Aerospace: In the aerospace field, FFKM seals are able to withstand extreme temperature changes and are suitable for use in engines and outer space equipment.

Mechanical Manufacturing: Used in pumps, compressors and other mechanical equipment to provide effective sealing solutions.

Automotive Industry: Applied to engines, transmissions and other key components to ensure sealing performance and durability.