FFKM O-rings

FFKM O-Rings

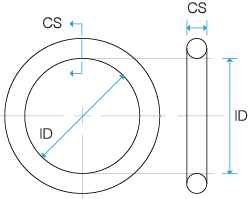

Fully molded FFKM O-rings for critical sealing applications. Standard and custom sizes available in a range of high performance elastomer materials.

We hold a comprehensive range of molds for international standard O-ring sizes BS1806, BS4518, AS568 and ISO3601. For non-standard O-ring seals we can produce custom tooling in-house very quickly, providing cost effective solutions and a more responsive service. Our manufacturing lead-times are some of the shortest in the sealing industry.

With an unrivalled range of elastomer materials available, Uninovo has an elastomer for every application, with performance characteristics that withstand high temperature, high pressure and aggressive chemical applications.

Perfluoroelastomer (FFKM) is the most chemically resistant elastomer available and is effectively a rubber form of PTFE.Perfluoroelastomer sealing materials are at the leading edge of polymer technology – for unrivalled resistance to chemicals and extreme temperatures.

FFKM O-rings and seals are used in critical sealing applications where purity, high temperatures, chemical resistance and retention of sealing force are paramount.

FFKM O-rings and seals manufactured from perfluoroelastomers offer the ultimate sealing performance and reliability.

FFKM Material Characteristics

1. High temperature resistance: FFKM’s temperature resistance range can reach 320°C or even higher, which makes it perform well in high-temperature hydraulic and vacuum systems.

2. Chemical stability: FFKM material has a wide range of chemical inertness and can resist corrosion from most chemicals, including strong acids, strong alkalis, solvents, oils, etc.

3. Low gas permeability: Due to the high density of fluorine atoms in FFKM material, its gas permeability is extremely low, suitable for applications requiring airtightness, such as semiconductor manufacturing and vacuum systems.

4. Mechanical strength and elasticity: FFKM material has excellent mechanical strength and elasticity and can withstand high pressure and dynamic loads. Its high tensile strength and modulus make it perform well in dynamic sealing applications.

5. Compression set resistance: FFKM material has extremely low compression set, and its sealing performance will not be significantly reduced due to compression, thereby extending its service life.

6. Wear and tear resistance: FFKM material has excellent wear and tear resistance and can remain stable in harsh environments.

Application Areas

Chemical Industry: FFKM seals are able to withstand a wide range of corrosive chemicals and are widely used in pipe, valve and reactor seals to ensure safe and effective sealing.

Semiconductor Manufacturing: In the semiconductor production process, FFKM seals are used in vacuum systems and gas sealing applications to ensure no leaks and maintain a clean environment.

Pharmaceutical Industry: Due to its FDA compliance, FFKM seals are widely used in pharmaceutical equipment to ensure safety and reliability when in contact with pharmaceuticals.

Oil and Gas: FFKM seals perform well under high temperature and pressure conditions and are suitable for critical applications such as oilfield equipment, downhole tools and control valves.

Aerospace: In the aerospace field, FFKM seals are able to withstand extreme temperature changes and are suitable for use in engines and outer space equipment.

Mechanical Manufacturing: Used in pumps, compressors and other mechanical equipment to provide effective sealing solutions.

Automotive Industry: Applied to engines, transmissions and other key components to ensure sealing performance and durability.