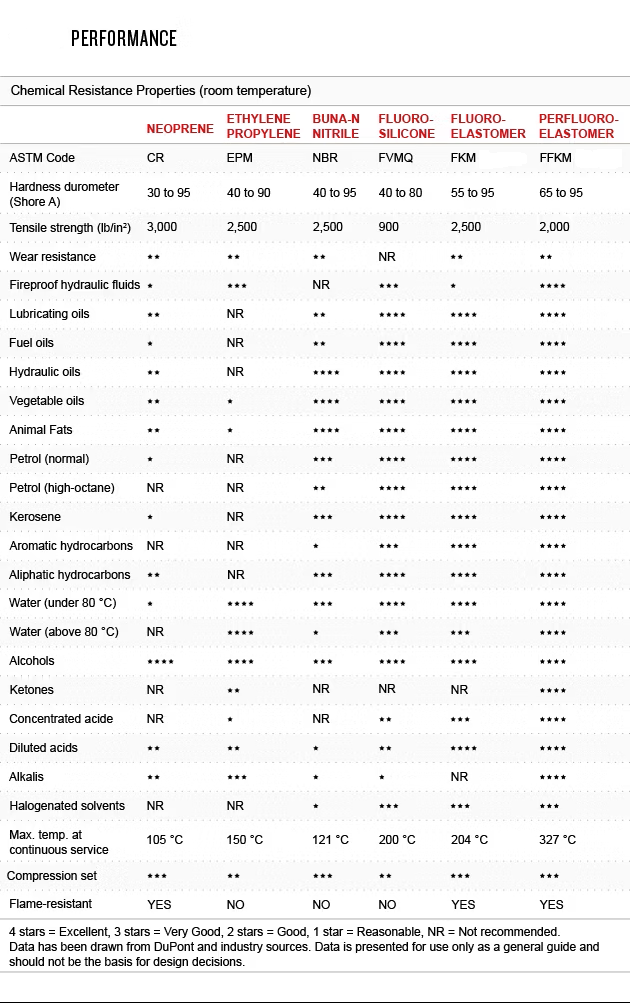

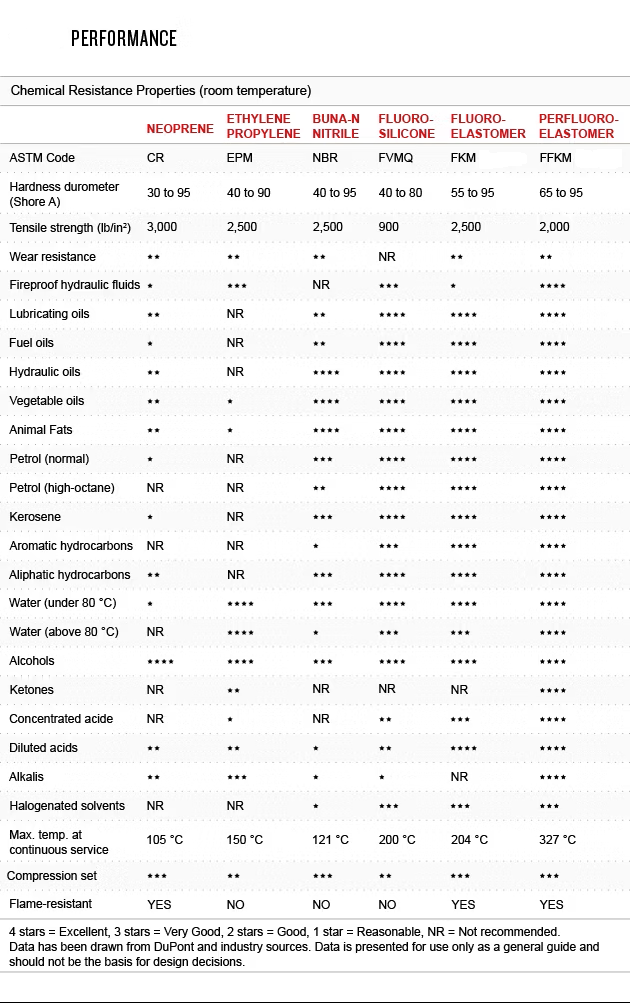

FFKM Parts Chemical Resistance

2025/6/24 view:

FFKM Parts Chemical Resistance Performance

Perfluoroelastomer (FFKM) parts withstand attack from more than 1,800 chemicals, solvents and plasmas. The FFKM product line delivers outstanding performance in aggressive process environments. Whether it’s resistance to acids, amines, plasma, ultrapure de-ionized water or strong bases, by selecting the FFKM product that is best suited to a specific application, manufacturers can improve seal performance in their operating environment.FFKM parts are available in a number of different compounds that are formulated to optimize properties and give the best possible performance in various chemicals and temperatures. The FFKM Application Guide can help users select the preferred product for temperature and chemical resistance.

Perfluoroelastomer (FFKM) parts withstand attack from more than 1,800 chemicals, solvents and plasmas. The FFKM product line delivers outstanding performance in aggressive process environments. Whether it’s resistance to acids, amines, plasma, ultrapure de-ionized water or strong bases, by selecting the FFKM product that is best suited to a specific application, manufacturers can improve seal performance in their operating environment.FFKM parts are available in a number of different compounds that are formulated to optimize properties and give the best possible performance in various chemicals and temperatures. The FFKM Application Guide can help users select the preferred product for temperature and chemical resistance.

Minimal Swell

Chemically induced swelling can cause O-rings and sealing components made of other elastomers to extrude out of seal grooves, resulting in seal failures. FFKM parts resist extreme volume swell when exposed to a wide variety of chemicals and solvents, including concentrated nitric acid, sodium hydroxide, ethylene diamine and steam. They have proven to be a cost-effective solution in sealing situations that require the greatest resistance to harsh chemical environments and high temperatures.

Minimal Swell

Chemically induced swelling can cause O-rings and sealing components made of other elastomers to extrude out of seal grooves, resulting in seal failures. FFKM parts resist extreme volume swell when exposed to a wide variety of chemicals and solvents, including concentrated nitric acid, sodium hydroxide, ethylene diamine and steam. They have proven to be a cost-effective solution in sealing situations that require the greatest resistance to harsh chemical environments and high temperatures.

- Pre:Chemical resistance of rubber 2025/6/24

- Next:Perfluoroelastomer, FFKM 2025/6/18